The performance of a lead rubber bearing depends heavily on the quality of its materials and the precision of its manufacturing process. The rubber compound, typically natural rubber or high-damping synthetic rubber, is formulated to provide consistent elasticity, durability, and resistance to aging. This rubber is layered with thin steel plates, which are treated to prevent corrosion and ensure strong adhesion during vulcanization. The lead core, made from high-purity lead, is chosen for its ability to undergo plastic deformation repeatedly without fracturing, making it ideal for energy dissipation. Each material is tested rigorously for mechanical properties, chemical stability, and environmental resilience before being integrated into the final product.

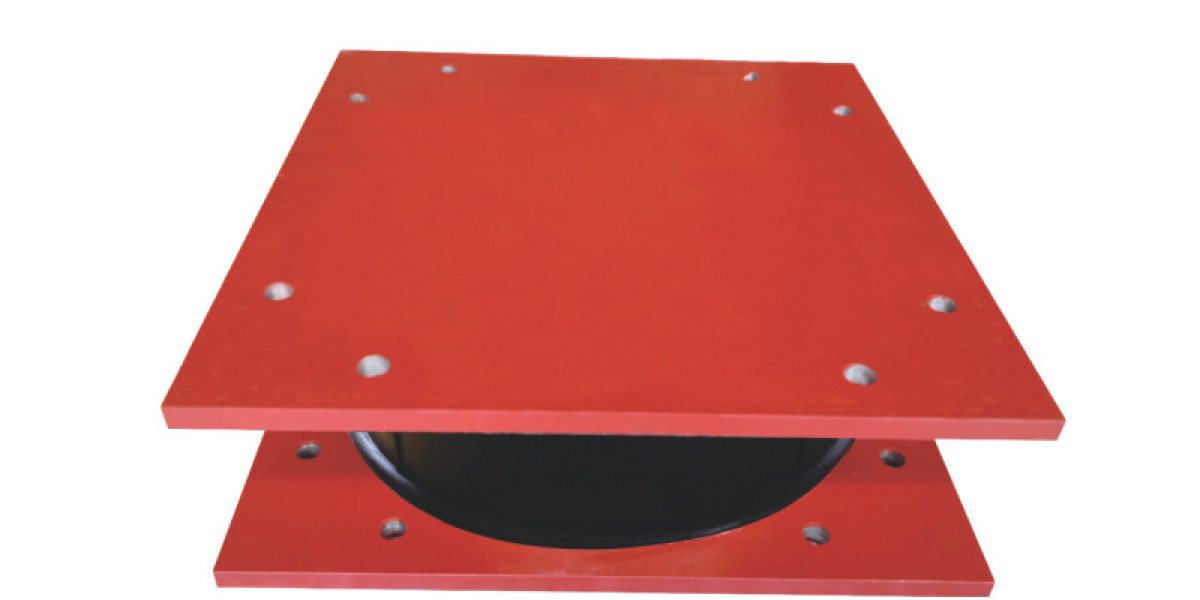

Manufacturing a lead rubber bearing begins with preparing the steel plates and rubber sheets to exact dimensions. The plates are often sandblasted and coated with a bonding agent to enhance adhesion. These components are then stacked alternately in a mold, with the lead cylinder positioned centrally. The entire assembly is subjected to high temperature and pressure in a vulcanization press, which chemically bonds the rubber to the steel, creating a monolithic unit. This process ensures uniform distribution of materials and eliminates potential weak points. After curing, the bearing undergoes finishing processes, such as trimming excess rubber and applying protective coatings to exposed metal surfaces.

Quality control is integral throughout production. Samples from each batch are tested for shear stiffness, damping capacity, compression strength, and fatigue resistance under simulated seismic conditions. Non-destructive evaluations, including X-ray or ultrasonic scanning, may be used to detect internal flaws. Manufacturers also conduct prototype testing on full-scale bearings to verify performance against international standards, such as those set by ASTM or ISO. These stringent procedures ensure that every lead rubber bearing meets the reliability and safety requirements necessary for critical seismic applications.

The advancement of manufacturing technologies has enabled the production of lead rubber bearing with customized properties for specific projects, such as larger diameters for heavy infrastructure or specialized compounds for extreme climates. Ongoing research focuses on improving material sustainability, such as developing recycled rubber composites or alternative energy-dissipating metals. The meticulous attention to material science and fabrication excellence underscores the role of the lead rubber bearing as a high-integrity component in seismic protection systems, trusted by engineers to perform under the most demanding conditions.