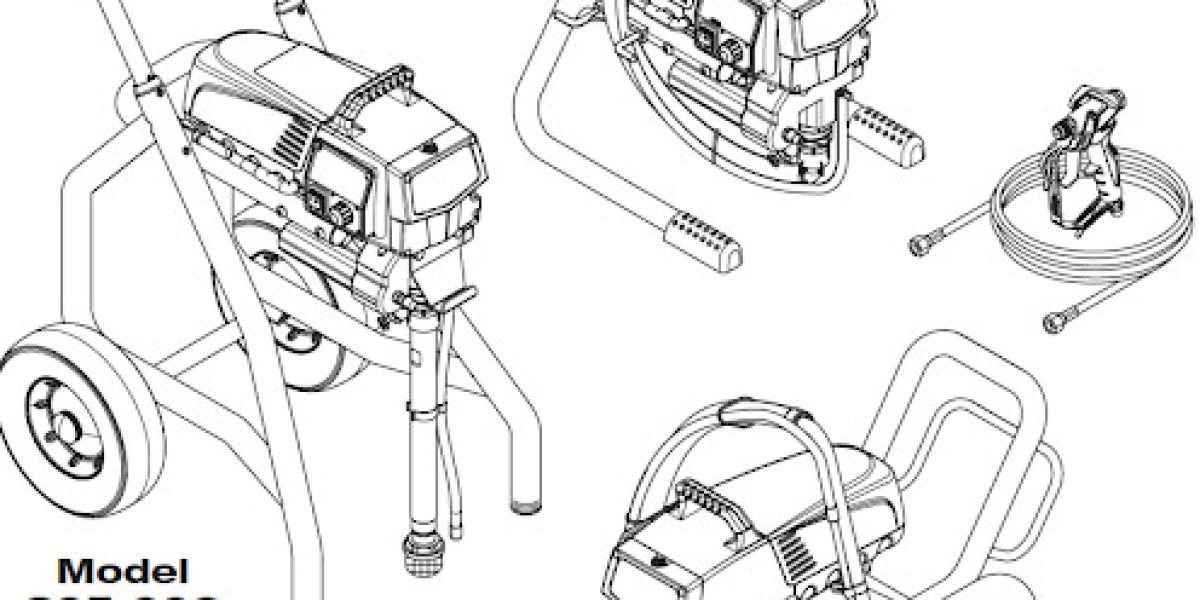

If you own a Titan 540 paint sprayer, you already know it’s a dependable workhorse for both professionals and DIY users. But like any high-performing tool, it needs regular maintenance to stay in top shape. Whether you’re spraying walls, furniture, or industrial surfaces, proper upkeep ensures consistent spray quality, prevents costly breakdowns, and extends the life of your sprayer.

In this article, we’ll break down which Titan 540 parts are crucial for routine maintenance, what each part does, and how often you should check or replace them. Think of it as your over-the-phone guide to keeping your Titan 540 running smoothly!

1. Fluid Section Assembly – The Heart of the Sprayer

The fluid section of your Titan 540 is where all the paint flow action happens. It’s made up of several small but vital components that directly affect spray performance. If you notice inconsistent pressure or poor atomization, the issue likely lies here.

First, the piston rod and packings should be checked regularly. These are the parts that handle high-pressure movement, and they can wear down from constant use. Over time, paint debris and friction can cause the packings to leak, resulting in reduced spray power. Replacing these components during routine maintenance helps maintain strong, even pressure.

Next up are the seals and O-rings. These rubber components keep the paint from leaking and maintain the right level of suction inside the pump. If you see any paint seepage or air leaks, that’s your cue to inspect the seals. A simple replacement kit can restore your sprayer’s performance in no time.

Lastly, keep an eye on the inlet valve and outlet valve. These valves control the flow of paint into and out of the pump. If they become clogged or worn, your sprayer might start pulsing or sputtering. Cleaning or replacing them every few months is a small task that prevents big issues later.

2. Filters and Strainers – The Guardians Against Clogs

If your sprayer suddenly stops working or sprays unevenly, there’s a good chance it’s due to a clogged filter. The Titan 540 comes equipped with multiple filters designed to prevent debris from entering the spray system.

Start with the manifold filter, located near the fluid outlet. This filter traps fine particles before they reach the hose and gun. Depending on how often you spray, you should clean or replace it weekly or after every big job. A clean filter ensures smooth paint flow and prevents nozzle blockages.

Then there’s the suction filter, which sits at the end of the suction tube. This part catches large debris before the paint even enters the pump. If you’re spraying thicker materials like latex or primers, you’ll want to clean this filter frequently to avoid heavy buildup.

Finally, the gun filter plays an equally important role. It’s the last line of defense against clogs in the spray tip. Regular cleaning and replacement of this filter help you maintain that fine, professional finish without any splatter or uneven texture.

3. Spray Tips and Guards – The Key to a Perfect Finish

No matter how well you maintain your sprayer, worn-out spray tips can ruin your results. The spray tip determines your spray pattern, paint flow, and overall coverage. For the Titan 540, it’s one of the most frequently replaced parts.

Each time you use your sprayer, paint particles wear down the inside of the tip slightly. After many uses, the opening widens, causing uneven spray patterns and wasted paint. Most pros replace their spray tips after 40–50 gallons of paint use, but this can vary based on material type.

The tip guard is another essential part. It not only keeps you safe from high-pressure paint injection but also helps keep your tip clean and centered. Make sure to inspect it regularly for cracks or damage—especially if you’ve dropped your gun or bumped it during work.

And don’t forget the tip gasket. This small rubber piece ensures a tight seal between the tip and the gun. If you ever notice leakage or dripping around the tip area, it’s a sign that the gasket needs replacement.

4. Hose and Gun Maintenance – Keeping Flow Consistent

Your spray hose and gun assembly are like the arteries of your sprayer system. They carry pressurized paint from the pump to your project. Any leak, crack, or clog here can dramatically affect performance.

First, inspect your spray hose before every use. Look for any visible cracks, kinks, or soft spots. Hoses endure high pressure, so even a small weakness can cause sudden bursts or reduced flow. It’s a smart move to replace your hose every year or two, depending on how heavily you use it.

Next, let’s talk about the spray gun trigger assembly. If your trigger feels stiff or unresponsive, it might be time to lubricate or rebuild it. A gun repair kit for the Titan 540 usually includes replacement springs, seals, and trigger pins. Keeping the gun in top condition means smoother spraying and less fatigue during long jobs.

Finally, after every session, clean both the hose and gun thoroughly. Use a compatible cleaning solution—never just water for oil-based paints. Flushing your sprayer properly prevents dried paint from clogging internal parts and keeps the entire system ready for the next use.

5. Piston, Cylinder, and Packings – The Power Trio

The piston, cylinder, and packings work together to generate the pressure that makes your Titan 540 so powerful. Without proper maintenance, these components can wear out quickly and lead to pressure loss or total failure.

Start with the piston rod. Over time, it can develop scratches or corrosion, especially if the sprayer isn’t cleaned regularly. A damaged piston rod can tear through packings and cause leaks. Inspect it monthly, and replace it if it shows visible wear.

The cylinder or pump housing should also be checked periodically. It’s where the piston moves up and down, and if paint residue builds up here, it can cause friction and overheating. Keeping it clean ensures smoother operation and longer part life.

Lastly, the packing set deserves special attention. It’s a combination of leather and Teflon rings that seal the fluid section. Worn packings are one of the most common causes of pressure problems in airless sprayers. Replacing them as part of your maintenance routine will prevent downtime and keep your Titan 540 performing at its best.

6. Electrical and Pressure Control Components – The Brain of the Machine

While mechanical parts get most of the attention, the electrical and pressure control system in the Titan 540 is equally important. These parts control how much paint pressure you get and ensure smooth operation.

Start by checking the pressure control knob and transducer. If your sprayer pressure fluctuates or doesn’t build up properly, it could be due to a faulty control sensor. Keeping the transducer clean and replacing it when needed ensures consistent spray output.

Next, inspect the motor brushes. These small carbon parts transfer electricity to the motor and wear down over time. If your sprayer suddenly loses power or makes unusual sounds, worn motor brushes might be the culprit. Replacing them is quick and inexpensive but makes a huge difference in performance.

Finally, the on/off switch and wiring should be examined for any frayed connections or moisture buildup. Even small issues here can lead to electrical shorts or intermittent power failures. Regular inspection ensures your Titan 540 stays reliable for every project.

7. Cleaning and Lubrication – The Unsung Heroes of Maintenance

You can replace every part you want, but without regular cleaning and lubrication, your Titan 540 won’t last long. Proper maintenance keeps moving parts in sync and prevents rust, corrosion, and paint buildup.

After every job, run a cleaning solution through the system. For water-based paints, flush with water followed by a storage fluid. For oil-based materials, use the appropriate solvent. This keeps your valves and hoses clear and prevents clogging.

Lubricate the piston rod and packings regularly using Titan’s recommended pump oil. A few drops after every cleaning session can extend part life significantly. Never use random oils—they might damage seals or gum up over time.

Finally, store your sprayer properly. Always release the pressure before storage and keep it in a cool, dry place. Cover it with a dust guard or cloth to prevent debris buildup around the filters and motor vents.

Conclusion: Keep Your Titan 540 Running Strong

Maintaining your Titan 540 parts doesn’t have to be complicated. Think of it as giving your sprayer a quick health check after every project. Regular inspection, timely replacement of worn components, and thorough cleaning will save you from major repairs and keep your sprayer performing like new.

From the fluid section and filters to the electrical controls and spray tips, every part plays a role in smooth, efficient operation. By following this maintenance guide, you’ll not only get longer life from your Titan 540 but also achieve consistent, professional-grade finishes on every job.