The design of a plastic cup mould is a specialized field of toolmaking that balances intricate detail with the demands of high-speed, automated production. Every feature of the final cup, from its rim curl and base geometry to subtle branding textures, must be precisely machined into the mould steel. Moulds are commonly made from pre-hardened steels like P20 or H13 for good polishability and wear resistance. The cavity and core are first machined to near-net shape, then finished through electrical discharge machining (EDM) for fine details and hand-polished to a mirror finish to ensure easy part release and a glossy cup surface.

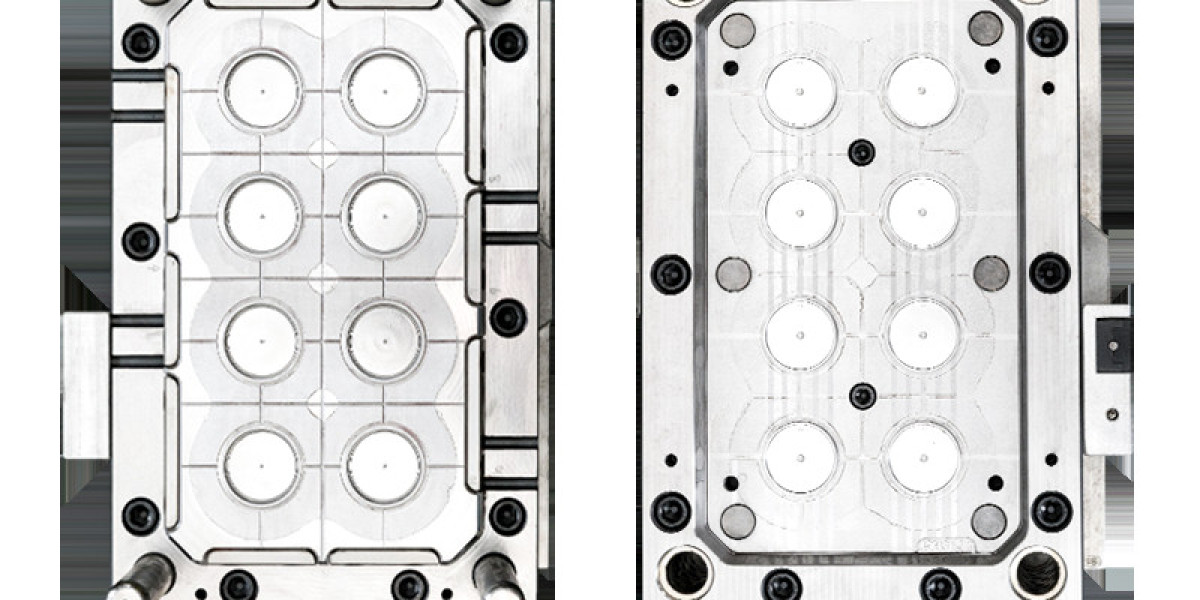

Thermal management is a cornerstone of the design. A network of cooling channels is drilled as close as possible to the moulding surfaces to control solidification. Efficient cooling minimizes cycle time, prevents warpage, and ensures dimensional stability. The feed system is another critical element; it includes the sprue, runners, and gates that channel plastic from the injection machine nozzle into the cavity. For multi-cavity moulds, which produce several cups per cycle, the runner system must be balanced so that each cavity fills simultaneously and uniformly to guarantee consistent cup weight and quality.

The mould is also equipped with guide pins and bushings for perfect alignment between halves and vents to allow trapped air to escape during injection. The meticulous engineering behind a plastic cup mould translates directly into manufacturing efficiency. A well-designed mould can run for millions of cycles with minimal downtime, producing cups with consistent wall thickness and mechanical strength, which is essential for both performance in use and for reliable high-speed stacking and packaging.